Sheet Metal Rolling

Linders Specialty Company has built up sheet metal rolling expertise for multiple size ranges to meet your requirements for your project accurately. We can produce rolled sheet metal parts repetitively to within very tolerances.

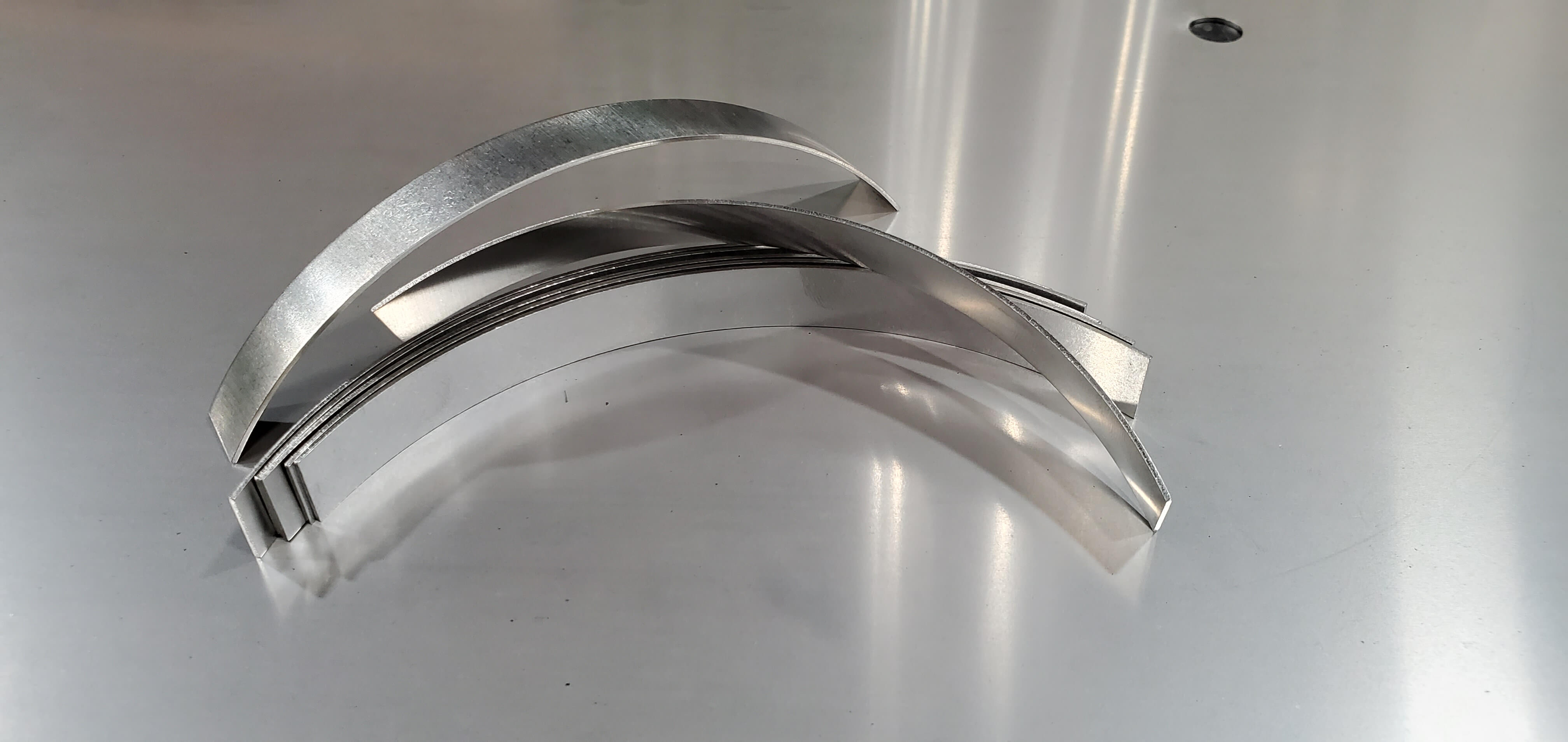

Our Acrotech urethane production roll has capabilities like no other. It is the largest and widest machine of its type available; equipped with additional smaller top rolls for rings down to 1 ½” inches in diameter. It can roll parts with no flats in up to 3/16” thick mild steel or ¼” thick aluminum up to 30” wide. Typical three point rolling machines will leave kinks or require secondary operations to remove fillers to get a smoothly rolled part. Our process does it in one quick operation.

By making a low-cost mandrel for each part, repeatability and efficiency is achieved through high-speed production – often times with just one rolling pass. Prototypes can often be made using existing tooling that is sufficiently similar. Our multiple machines allow us to select the correct equipment to use the material that you need include this small-range plate roller.

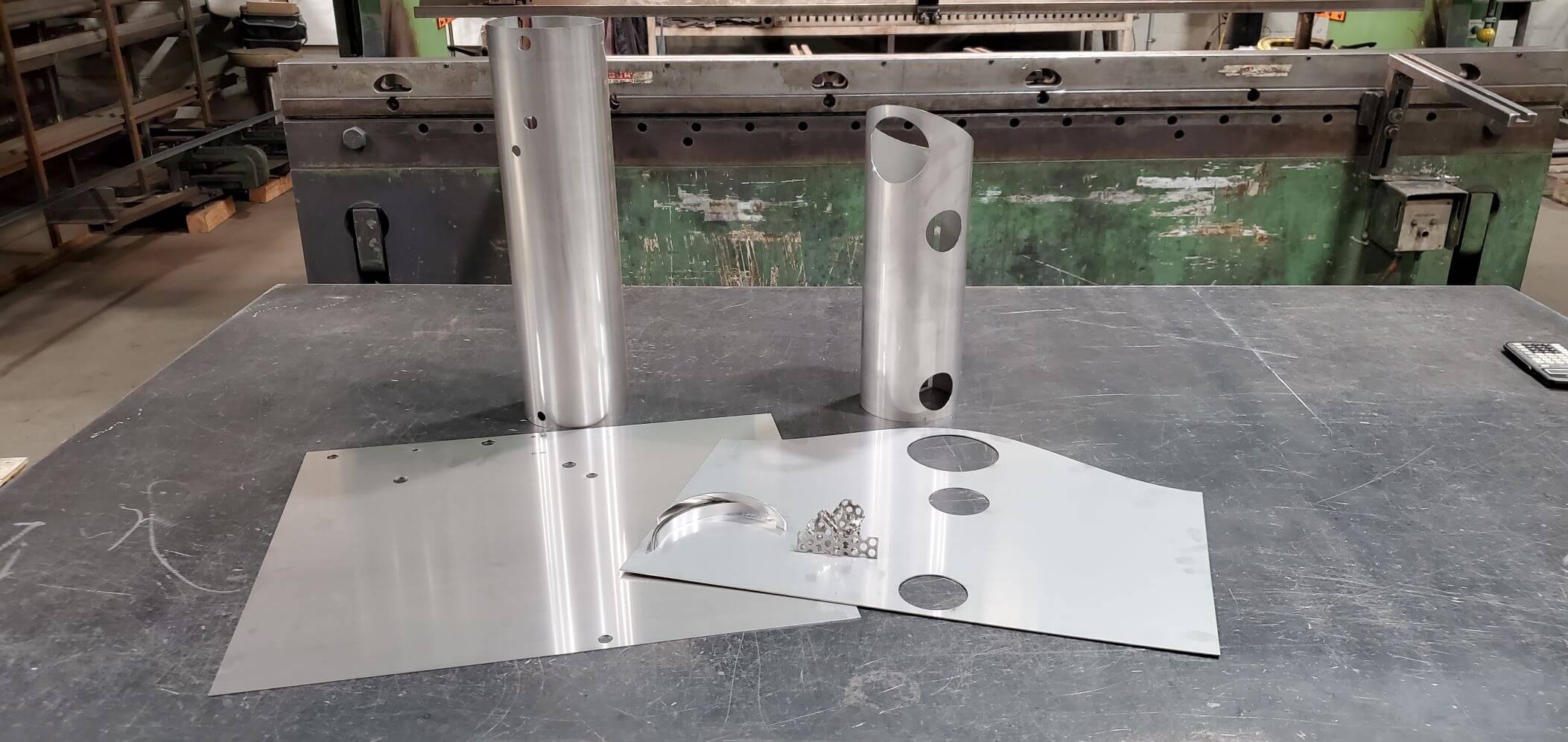

Sheet Metal Fabrication Services

We can roll full cylinders, partial cylinder segments, and specialized components consisting of varying radii along a single piece. This can be done with mild steel, stainless steel, or aluminum with very negligible surface scratching.

We are experts on:

- Full cylinders

- Partial cylinder segments

- Varying radii components

These can be made with mild steel, stainless steel, or aluminum with negligible surface deformation. We also can handle galvanized sheet metal as well as painted and polished metals.

Our broad span of equipment ensures that we have the right method to complete your job even with a demanding delivery schedule.

Request a quote for your sheet metal forming application from our experienced staff.

Additional Sheet Metal Rolling Services

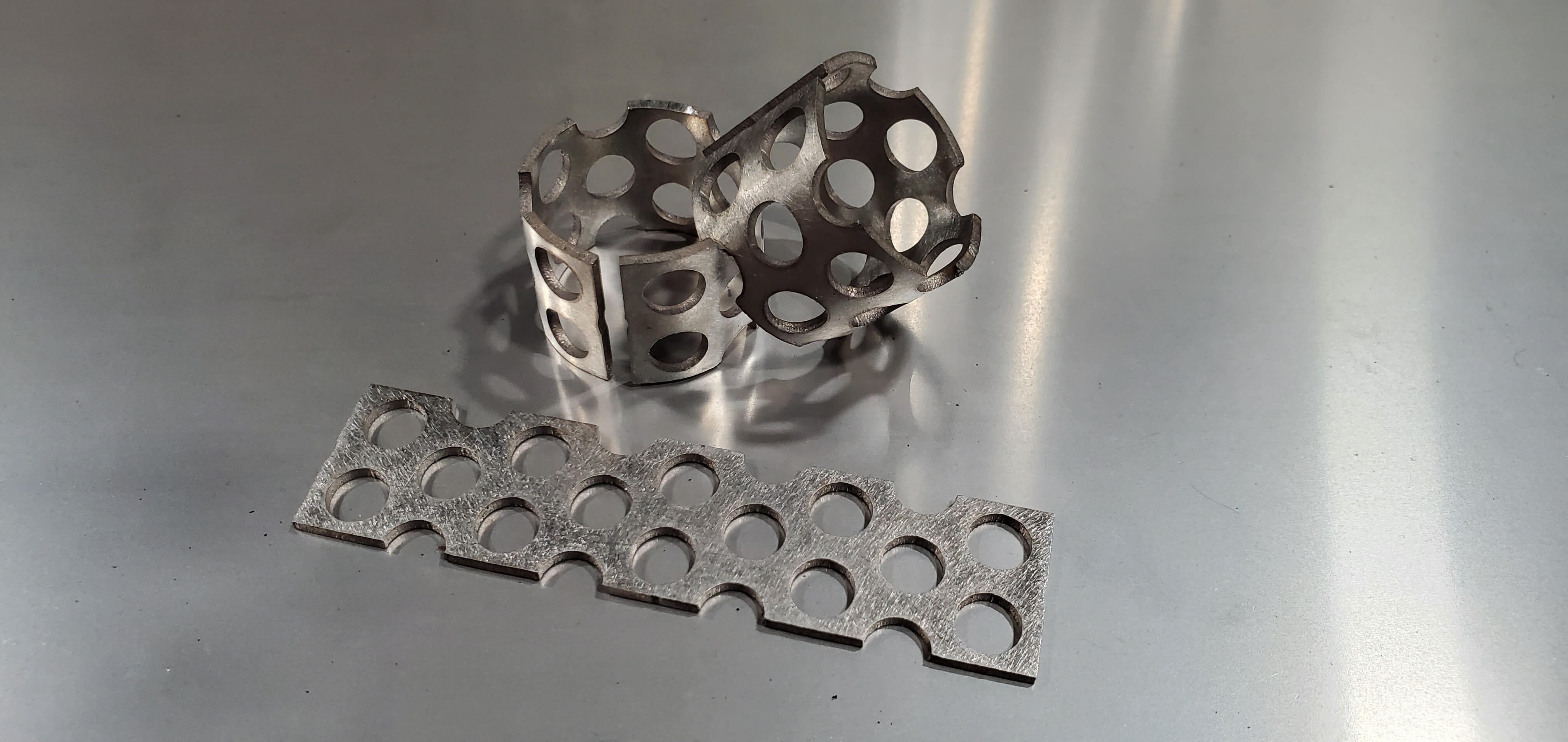

In addition to our basic sheet rolling, Linders can also trim and bevel your parts and add fabrication services to the final metal product. We can add sawing, plasma plate burning or torch cutting as well as punching or drilling holes and adding additional assemblies. Surface finishing such as paint, powder coating, sandblasting and corrosion prevention are available.

Sheet Metal Forming Applications

Our sheet rolled components have been widely used for:

- Mounting straps

- Tank collars

- Ventilation components

- Small cylindrical parts

- Polished metal components

- Plus many more

Contact Linders Specialty Company for Sheet Metal Rolling Today

Proud to offer over 40 years of experience in sheet metal fabrication, Linders Specialty Company incorporates proprietary techniques and the latest equipment to produce quality sheet metal fabrication services. With sheet metal forming capabilities that achieve minimal distortion, we can fabricate your rolled sheet metal components to exact standards. In addition, we offer metal cutting and forming, welding services and other finishing services to provide complete components ready for use.

Contact us with questions about our sheet metal fabrication services, give us a call, or request a quote today.